TIME and COST SAVINGS

Real Engineering Solutions

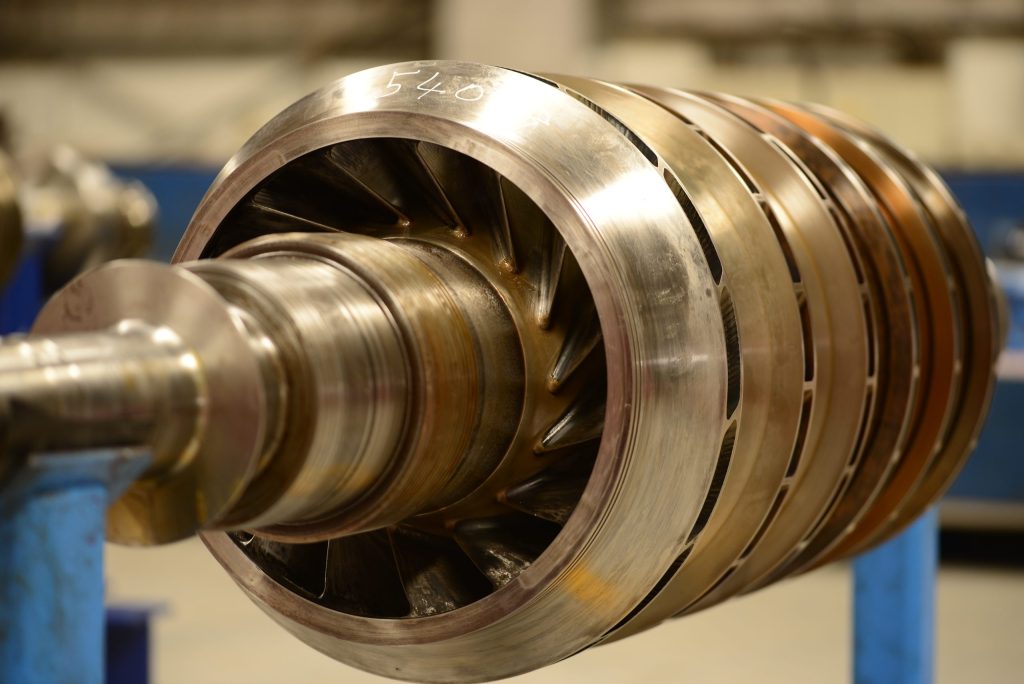

Reverse engineering is a process that aims to understand the inner workings, components and design of a product or system. In this process, the design of an existing product is examined, its components are analyzed and its functions are tried to be understood.

As SmartS Engineering, Reverse Engineering solutions include locally manufactured parts that comply with original equipment performance and quality expectations, while also incorporating relevant improvements in performance and manufacturing methodologies.

PRODUCT COVERAGE

SCANING OF ORIGINAL COMPONENT

Our reverse engineering process consists of a series of steps. First, detailed information and documents about the product or system are obtained from our customer. Then, the product is physically examined and its components are analyzed. Finally, new design proposals are developed in line with the data obtained.

CAD MODEL

Reverse engineering offers many advantages. A model of the part is drawn on the computer. Understanding the design of an existing product is an important step in developing new products or improving existing products. It also provides a competitive advantage and allows you to get ahead in the market.

ASSEMBLY

After the model is scanned and drawn with CAD programs during the assembly phase, the part is carefully assembled and tested. If the part that passes the testing phase works without any problems, the process is completed successfully.